Leading Oil & Gas Company Achieves 90% Efficiency with Custom AI

Overview

Client:

A prominent international oil & gas company exploration and production company (Client name withheld for confidentiality)Industry:

Oil & GasChallenge:

Manual, time-consuming, and error-prone oil chemical analysis impacting operational efficiency and decision-making.In the demanding environment of the oil & gas industry. The precise and timely analysis of oil chemical compositions is paramount. It’s crucial for everything from optimizing drilling fluids and reservoir management to ensuring pipeline integrity and meeting stringent environmental regulations. Our client, a leading international player in oil & gas company exploration and production. Was facing significant challenges with their existing chemical analysis processes.

Their traditional methods relied heavily on manual data input, visual inspection, and fragmented software tools. This labor-intensive approach led to several critical issues:

High Manual Effort & Human Error: Chemists and technicians spent countless hours manually inputting data from lab instruments, comparing results against vast historical databases, and preparing reports. This process was susceptible to human error, which could have costly implications for operational decisions and regulatory compliance.

Slow Turnaround Times: The sheer volume and complexity of analyses meant that critical insights were often delayed. This lag directly impacted decision-making speed for drilling adjustments, production optimization, and maintenance scheduling.

Inconsistent Data Interpretation: Variations in analyst experience and methodologies could lead to inconsistencies in interpreting complex chemical patterns, potentially missing subtle but important indicators of equipment wear, fluid contamination, or reservoir changes.

Scalability Limitations: As the company expanded its operations and increased its analytical needs, scaling the manual process became a major bottleneck, requiring disproportionate increases in staffing and resources.

Inefficient Resource Allocation: Highly skilled chemists were tied up in repetitive data processing tasks rather than focusing on complex problem-solving and innovation.

The client recognized that modernizing this core function was not just about efficiency; it was about enhancing safety. So, improving operational performance, and ensuring a competitive edge through faster, more reliable data-driven decisions.

In the demanding environment of the oil & gas industry. The precise and timely analysis of oil chemical compositions is paramount. It’s crucial for everything from optimizing drilling fluids and reservoir management to ensuring pipeline integrity and meeting stringent environmental regulations. Our client, a leading international player in oil & gas company exploration and production. Was facing significant challenges with their existing chemical analysis processes.

Their traditional methods relied heavily on manual data input, visual inspection, and fragmented software tools. This labor-intensive approach led to several critical issues:

- High Manual Effort & Human Error: Chemists and technicians spent countless hours manually inputting data from lab instruments, comparing results against vast historical databases, and preparing reports. This process was susceptible to human error, which could have costly implications for operational decisions and regulatory compliance.

- Slow Turnaround Times: The sheer volume and complexity of analyses meant that critical insights were often delayed. This lag directly impacted decision-making speed for drilling adjustments, production optimization, and maintenance scheduling.

- Inconsistent Data Interpretation: Variations in analyst experience and methodologies could lead to inconsistencies in interpreting complex chemical patterns, potentially missing subtle but important indicators of equipment wear, fluid contamination, or reservoir changes.

- Scalability Limitations: As the company expanded its operations and increased its analytical needs, scaling the manual process became a major bottleneck, requiring disproportionate increases in staffing and resources.

- Inefficient Resource Allocation: Highly skilled chemists were tied up in repetitive data processing tasks rather than focusing on complex problem-solving and innovation.

The client recognized that modernizing this core function was not just about efficiency; it was about enhancing safety. So, improving operational performance, and ensuring a competitive edge through faster, more reliable data-driven decisions.

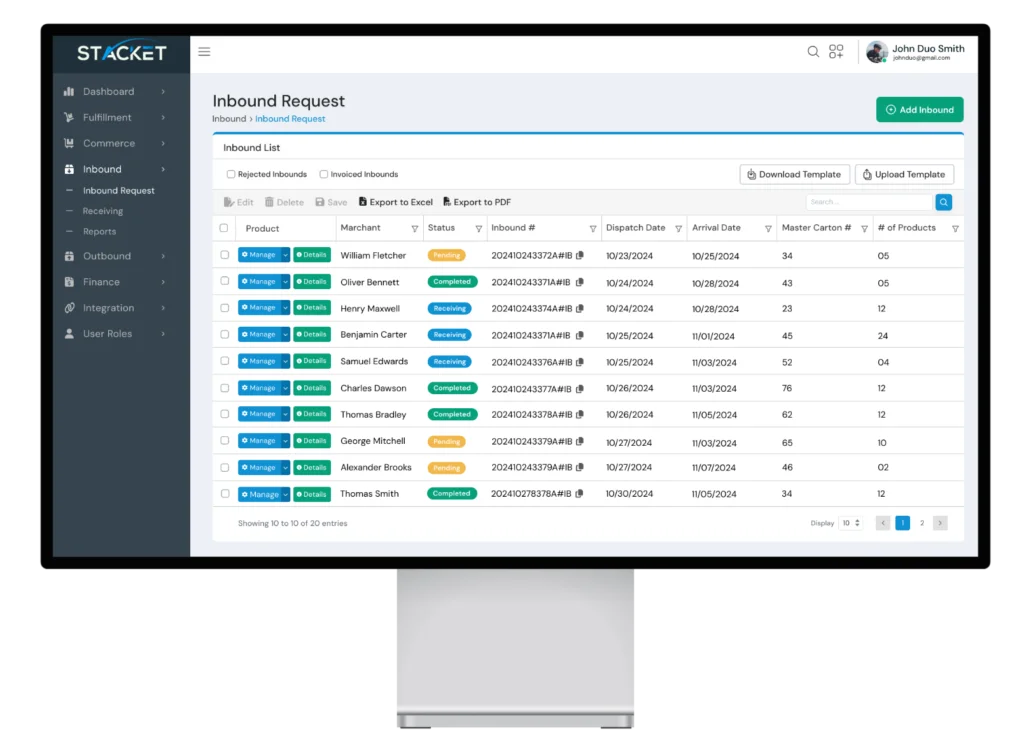

Optimize warehouse operations with AI-powered inventory tracking, shipping carrier integration, and customizable workflows.

Real-time inventory tracking

Seamless integration with shipping carriers.

Advanced reporting and analytics tools.

Customizable workflows for 3PL operations.

Benefits

Enhance engagement, save time, and improve efficiency with mobile-first HR solutions.

Increase operational efficiency and accuracy.

Reduce costs through optimized warehouse processes.

Scale your warehouse operations effortlessly.

JavaScript

Dot Net